What Does Indonesia Furniture Manufacturers Mean?

Table of ContentsThe Basic Principles Of Indonesia Furniture Manufacturers Rumored Buzz on Indonesia Furniture ManufacturersIndonesia Furniture Manufacturers Fundamentals ExplainedSee This Report about Indonesia Furniture ManufacturersIndonesia Furniture Manufacturers for DummiesThe Of Indonesia Furniture ManufacturersAll about Indonesia Furniture Manufacturers

As a developer, you have actually obtained lots of choices for transforming your customers'rooms right into artworks. However sometimes you understand a few tricks of the trade that a customer might not bank on. Personalized furniture can be one of those topics. Here's just how to educate your clients regarding the benefits of custom furnishings for their design job. When you get customized furniture, you do not obtainan impersonal style number. You obtain your style, precisely how you define. And you reach be a component of that choice process. After being a part of the layout experience, you will really feel greater contentment with your finished item of furnishings. Not just setting up items, yet really causing the visual in the room. By informing the personalized furnishings makers precisely what you desire and collaborating with them to make certain the layout is both pleasing and sound, you obtain a far better understanding of the furniture making process. And that brings a higher recognition of the way the furnishings adjustments your room. And if you are worried that you might require an adjustment in design in the future, no fears. Our group of customized furnishings producers is additionally proficient at applying new furniture, stitching, and accents to bring an older piece back to life.

Numerous modern furnishings pieces are prepared on setting up lines utilizing the fastest techniques readily available. Have you ever had a style job where you could not provide on a customer's demand just because a specific piece of furniture did not fit the location? Even simply a few inches can make a difference

when it comes to fitting furniture furnishings right into room spaceFlawlessly

As we commemorate Twinbru's journey, we welcome you to check out of furniture manufacturinga future that is much more lasting, efficient, and motivating.

There are some downsides to acquiring from a furniture producer. A furniture merchant is a firm that offers furniture made by numerous suppliers.

Not known Details About Indonesia Furniture Manufacturers

When you buy from a furnishings retailer, you're purchasing a furniture piece that's already been made and prepares to be delivered to your home. Among the advantages of purchasing from a furnishings merchant is that you can often see and touch the product prior to you get it.

At BH Furniture, we think in establishing new criteria for quality in the production of commercial furniture. Our dedication to technology has actually led us to welcome sophisticated automation technology, changing the method we produce furniture and moving us to the forefront of the sector. Gone are the days of hands-on labor dominating the manufacturing flooring.

Claim farewell to manufacturing hold-ups and overtime prices. This implies we not just meet yet exceed shipment target dates, providing our customers with a level of dependability that typical production approaches simply can't match.

Our manufacturing ability has soared, enabling us to satisfy the needs of even the biggest jobs without compromising on high quality. As your companion in industrial furnishings remedies, we can effortlessly scale our output to fit your needs, no matter the scale. While typical manufacturing depends greatly on manual labor, our automated systems have substantially decreased our reliance on a huge labor force.

Indonesia Furniture Manufacturers Can Be Fun For Anyone

Furnishings production is an intricate procedure that involves different stages, from designing and product choice to production and assembly - Indonesia furniture manufacturers. At each phase, there is an opportunity of flaws or mistakes that can endanger the top quality of the last item. To make sure that furnishings is of high quality, furniture suppliers apply quality assurance processes to identify and rectify any kind of issues that might develop throughout production

The inspection process should cover different aspects, such as setting up, finish, colour, style, product packaging, labelling, and marking. By applying an extensive inspection process, suppliers can guarantee their items meet the needed quality, security, and sturdiness needs. They also supply the adaptability to deal with concerns and make corrections before finishing the final product.

To ensure their furnishings products can endure numerous weather components, including sun, rainfall, snow, and wind, makers should consider globally recognized criteria that comprise inspections and testing. Here are a few of the standards to maintain in mind: ASTM F1561-03 is an international basic developed by the American Area of the International Organization for Testing Materials (ASTM).

The Main Principles Of Indonesia Furniture Manufacturers

UL 962 is an international safety standard developed by Underwriters Laboratories (UL), an independent worldwide supply security options business. The common uses to household and business home furnishings, including exterior furniture.

Reduced Manufacturing Prices: Applying quality control standards can minimise the chances of production faulty products, ultimately reducing manufacturing expenses and maximising the return on investment. Increased Consumer Satisfaction: Furnishings products that meet the required top quality requirements result in greater client satisfaction and commitment. This is crucial for preserving a solid reputation and getting an one-upmanship in the industry.

It aids to identify issues in the furniture this content and examine its performance and compliance with the called for high quality criteria. These samples commonly represent the various kinds of furnishings that they produce.

This may involve a combination of various examinations, consisting of strength testing, durability testing, safety testing, and environmental impact testing. The samples are after that checked for numerous quality parameters, such as strength, durability, safety, and environmental impact. The results are then reviewed to determine whether the products meet the required quality standards.

Not known Facts About Indonesia Furniture Manufacturers

A designer can understand the market patterns and be prepared with innovative styles ahead of time. Review right here: Just How DriveWorks Aids You to Minimize Lead Time in Production Developers often have to transform the sizes and shapes of furnishings at a moment's notice. These might have different visual and useful demands like front desk, and maintenance desk that vary in measurements.

on a typical platform. This assimilation of sales and ERP features brings even more visibility on price and rates. It basically presents CPQ like performance and permits producing fast quotes and quantities for budget analyses and completing orders. DriveWorks can auto-generate production shop illustrations with BOMs and DXFs for sheet cutting and punching.

Layout automation also boosts product high quality and decreases scrap. Field guideline files along with quantity departures are also created for retail store furniture setups. Integration amongst systems creates a seamless thread of operations and communication. All the stakeholders stay educated of requirements, ideas and last designs. Layout iterations and problems are reduced, and the shop flooring can start producing on the day of sales.

Indonesia Furniture Manufacturers Fundamentals Explained

It is an extremely competitive market, with businesses making every effort to keep up with transforming customer demands and the have a peek here most recent technological trends. Today's consumers are more most likely to favor furnishings that is personalized and made with lasting materials.

Alicia Silverstone Then & Now!

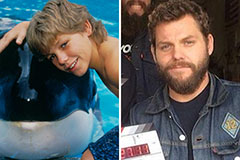

Alicia Silverstone Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!